But before diving into specific methods, it is worth exploring some key advantages of rapid prototyping, particularly its role in reducing time to market. By quickly converting digital designs into physical models, manufacturers and product developers can detect design flaws, collect user feedback, and implement improvements early in the development process. This streamlined approach accelerates the journey from concept to production-ready design, minimizing delays and helping products launch faster.

Selective Laser Melting

Selective laser melting (SLM), also called powder bed fusion, is a rapid prototyping method used primarily for complicated, strong metal parts. In this process, a fine metal powder is used, melted by an electron beam or high-powered laser layer by layer. Typically, parts and prototypes made using this process most often benefit the automotive and aerospace industries. In fact, SLM provides new enhancement opportunities for various components such as engines and transmissions. Additionally, it reduces costs by shortening development times and eliminating tooling needs. Surely, you can introduce new product improvements as well as reduce costs by manufacturing metal parts and prototypes using SLM.

Fused Deposition Modeling

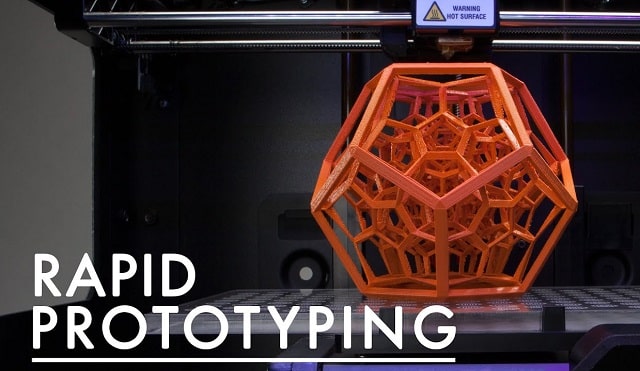

Next, fused deposition modeling (FDM) is another rapid prototyping method used for various applications. Often, they are used for modeling systems within advanced machinery. Using this technique, you can reduce costs and significantly shorten manufacturing timelines to create various manufacturing prototypes. Additionally, you can provide accurate representations of real-world use cases at drastically reduced manufacturing cost. Companies typically maximize the FDM process efficiency by building small part quantities with liquid plastic. In fact, most desktop 3D printers use FDM to create quick and cheap prototype products. Certainly, this is a great method for entrepreneurs looking to save on costs.

Foam Injection Molding

An additional rapid prototyping method, foam injection molding is often used for various custom products and a variety of consumer goods. These goods include protective gear, seating, water sports accessories, and more. Additionally, the foam used is more malleable, allowing a wider range of products and prototypes to be manufactured. Working with an injection molding company like Foam Creations, you can ensure that the materials used are free of harmful chemicals, heavy metals or latex. If you are thinking about launch a new lightweight, durable product, consider foam injection molding for your prototyping method. Certainly, this technique combines cost effectiveness, safety and usability.

Stereolithography

Stereolithography (SLA) is one of the oldest and most effective prototyping processes available to startups. The SLA offers 3D printing technology to transform liquid resin into hard plastic. Through photopolymeriation, you can create products with high visual quality, clarity and smoothness. Additionally, this method offers prototyping versatility by harnessing the various properties of industrial and engineering thermoplastics used. You can maximize these advantages by using SLA for detailed prototypes requiring smooth surfaces, such as molds and patterns for the dentistry, model making, and education industries. Further, it can help marketing a new product prior to full roll out. Definitely, consider SLA prototyping for visual quality and accuracy.

Selective Laser Sintering

Lastly, selective laser sintering (SLS) is another of the oldest rapid prototyping methods. The 3D printer uses a high powered laser to fuse materials like glass, plastic or ceramic together, creating a 3D object. Using this process, you can print complex or delicate objects since it doesn't require molds or additional tooling. In fact, SLS is commonly used to prototype customized products such as hearing aids and prosthetics. Additionally, SLS can be used to store prototypes digitally as .STL files, enabling your business to quickly modify, redesign, or reprint stored products. This way, prototypes move through the validation processes and become sellable products much faster. Of course, you can produce high-quality custom materials and guide them through the production pipeline faster with SLS.

Ramp Up Rapid Prototyping Products

There is a myriad of rapid prototyping methods for developing new products. For example, you can manufacture strong, complicated metal parts and prototypes using SLM. Second, significantly reduce costs and shorten development processes using FDM. Third, explore the unique prototypes possible with the safety and durability of using foam injection moldings. Next, you can leverage the visual quality and properties of your prototypes with SLA. Finally, produce high-quality custom materials and guide them through the production pipeline faster with SLS. When you are planning to develop a new product or line of products, consider these highly effective prototyping methods described above for quicker production.